- News

- Health

- Business Partners

- B2B-Services

- Expertise

- Company

bene builds on excellent trained specialists, state-of-the-art analytical technology

and transparent manufacturing and quality processes

in accordance with the highest German and international standards.

•Production, packaging

•Manual and repackaging, labelling

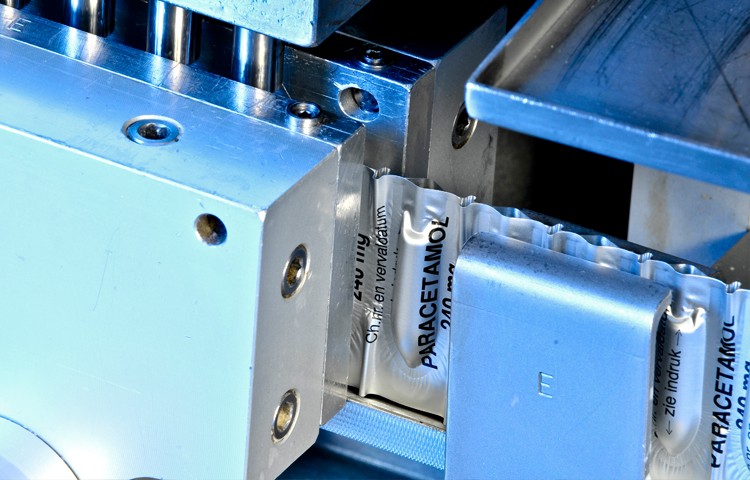

•Focus on suppositories, tablets, capsules

•Expert in the active substances Paracetamol, Ibuprofen, Diclofenac,

Pentosan Polysulphate, etc. > We carefully check your API requirements

•Experience in handling active substances with special legal requirements

•EU GMP certified

•Serialization on all lines: full FMD compliance

•Digital QMS

Your suppository specialist - extensive experience even with sensitive products.

From the world's first paracetamol suppository - Decades of experience in the production of suppositories

•Two modern filling and packaging lines: Sarong SAAS 15

•Suppositories or ovula

•Filling in thermoformable plastic (mono, duplex, triplex) and aluminum foils (duplex, triplex)

•Suppositories with different hard fat combinations for controlled release

•Specialized knowledge for products with high sensitivity and safety requirements (e.g. development

of suppositories for infants)

•Annual output: 100-150 million suppositories*.

•Batch sizes: 5-600 kg

•Suppository sizes: 0.5-3.6 g

*in 2-shift operation

Tablets & Capsules: Suppositories are our speciality, but we can do much more than that

•Direct tableting Fette PT 2090

•Encapsulation Syntegon GKF 1400 with downstream 100% weighing

•Blistering in thermoformable mono, duplex, triplex films (aluminum, PVC)

•Packing with IMA C80-A81

•Bottle packaging

•Fully automated in-process control of tablet mass, gap height and hardness

•Color camera during blistering

•Annual output: 500 million tablets*

•Batch sizes: 100-500 kg

•Individual tablet formats according to customer requirements or standard (round, oblong, oval)

•Capsule size according to customer requirements or 0 and 2 as standard

*in 2-shift operation